Laser welding: the assembly solution for batteries – E-Mobility

Laser welding is the excellence assembly process for the manufacture of modern batteries for the automotive, aerospace, rail and general e-Mobility sectors.

ES LASER offers laser machines for battery assembly.

Our teams study industrial laser machines that meet all your performance criteria.

E-mobility

Laser welding on batteries

Laser welding batteries

Laser Welding allows the assembly of a large number of materials, classic, hybrid and even the most reflective (copper, nickel, aluminium, steel, titanium, and alloys…) with important technical advantages compared to conventional technologies:

- No filler metal ;

- Sealing of welds ;

- Retained electrical and magnetic properties;

- High mechanical strength;

- Excellent repeatability;

- Very high welding rate;

- Welding depth > 1 mm ;

- All welding geometries: flat, circular, 3D, …

Many industrial customers trust our engineers and technicians to design and manufacture laser machines.

Do not hesitate to contact us!

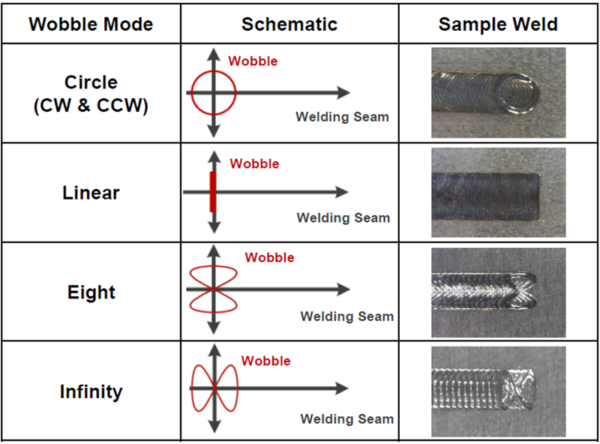

Laser welding technique of choice for batteries: WOBBLING

Compatible materials:

- Copper

- Aluminium

- Nickel

- Alloys

- (Al-Cu, Ni-CU, …)

- Steel

- Gold

- Polymers

- …

Laser Welding Applications :

- Welding of tabs

- Welding of outer covers

- Welding of electrodes

- Welding of internal connections

- Welding between cells

- …

New laser technologies have recently emerged to push the boundaries of laser welding:

- Continuous or pulsed, single or multi-mode, high power ytterbium fibre lasers;

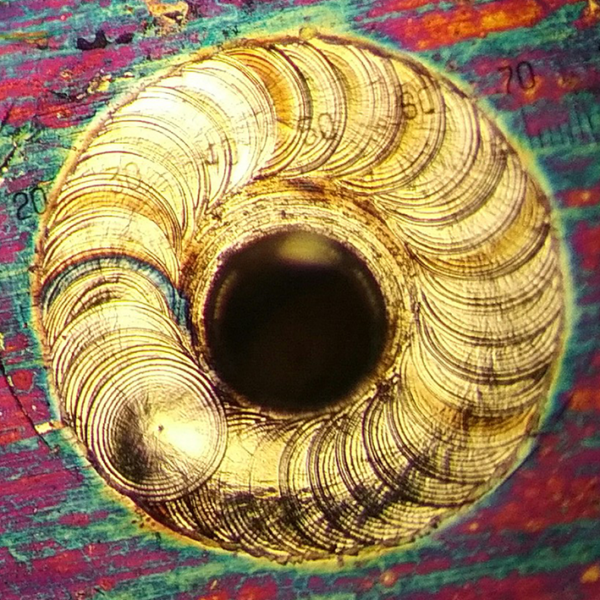

- Intelligent and ultra-fast oscillation systems, Wobbling type ;

- Multi KiloWatt Green Disc Lasers ;

- Multi-spot welding heads with energy distribution control;

- Welding heads with real time weld control and analysis,…