Laser welding – metals and plastics

The technical teams at ES LASER develop laser machines for welding of metals, welding of plastics and also welding of batteries. The technologies integrated in these laser machines allow for precise, fast, high quality and low cost.

Laser Welding allows the assembly of a large number of materials, classic, hybrid and even the most reflective (copper, nickel, aluminium, steel, titanium, and alloys…) with important technical advantages compared to conventional technologies.

welding of metals

Perfect welding

Welding thermoplastics

Find out more about the specificities:

Technique

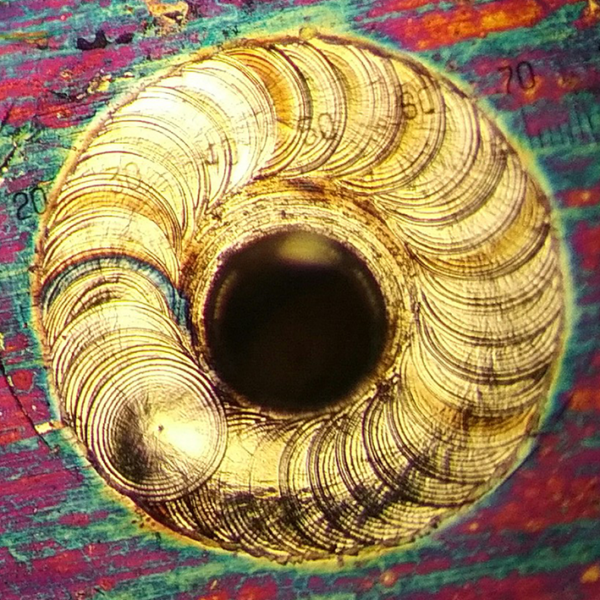

The welding of metals through the remarkable characteristics of laser technology. With the high energy density and the fineness of the laser beam, the targeted areas are melted and then quickly welded by cooling. The result is a solid weld on a small surface.

Advantages

The advantages of this technique make the laser solution indispensable for metal welding applications. in fact: no metal input, little or no deformation, high welding speed, excellent fineness, strength and repeatability of the weld. In addition, laser can be used to weld metals with high melting temperatures or high thermal conductivity as well as metals that cannot be welded using conventional techniques.

Plastic

In the case of laser welding of plastics, the welding is carried out by transparency. In fact, two materials to be welded, one transparent to the laser radiation and the other absorbent, are superimposed. The laser beam, focused at the junction of the two parts, passes through the transparent material and melts the absorbent material. The welding of the plastics is then achieved by the solid bond resulting from the rapid cooling of the assembly after the passage of the laser beam.

Methods

Laser can be used for a wide range of welding or brazing methods : spot welding, hybrid welding (combination of two welding techniques, e.g. laser and plasma), conduction welding, scanner welding, etc. Today, laser welding is mainly used in industry for its quality and speed of machining, its negligible collateral effects on the welded materials, its reliability and its versatility. Among the industries interested in this innovative technology are the medical sector, the watch and jewellery sector, the electronics and connector sector, the aeronautics sector, the shipbuilding sector and the automotive sector.

Ytterbium fiber laser source technology

For the manufacture of these laser machines for plastics or metals, ES LASER integrates the most efficient laser technology: Ytterbium fiber laser sources. Thanks to the specific characteristics of fiber optics, these sources are indispensable as laser welding tools for industrialists. They are: easy integration, flexibility, stability, automated and rapid beam deflection, robotisation of the welding process, laser welding carried out remotely, long service life, etc. Moreover, the quality of the laser beam (fineness of the laser spot, high energy density, spatial profile, etc.) obtained by these sources allows both surface (weld depth of 0.1 to 1 mm).

Depending on the welding application and the materials, the Ytterbium fiber laser source can emit a continuous or discontinuous beam (pulsed laser) with an average power ranging from 20 W to several tens of kW, such as for deep steel welds (25 mm) to 20 kW for automotive environments. Finally, welding of metals and plastics can be carried out using a single-mode or multimode laser fiber. In practice, a single-mode fiber (ten or so µm of optical core, high energy density, fine Gaussian spatial profile) will be preferentially used for fine or distance welding, because of the necessary focal distance. Multimode fibers (several tens to hundreds of µm of optical core) have a lower optical intensity and a more uniform energy distribution (flat or top hat type). They are therefore preferred for shallow, volume laser welding or to avoid degradation of the material subjected to too much energy (vaporisation).

Our team is at your disposal for any questions concerning laser machines for metals or plastics: contact@eslaser.com

And follow us!