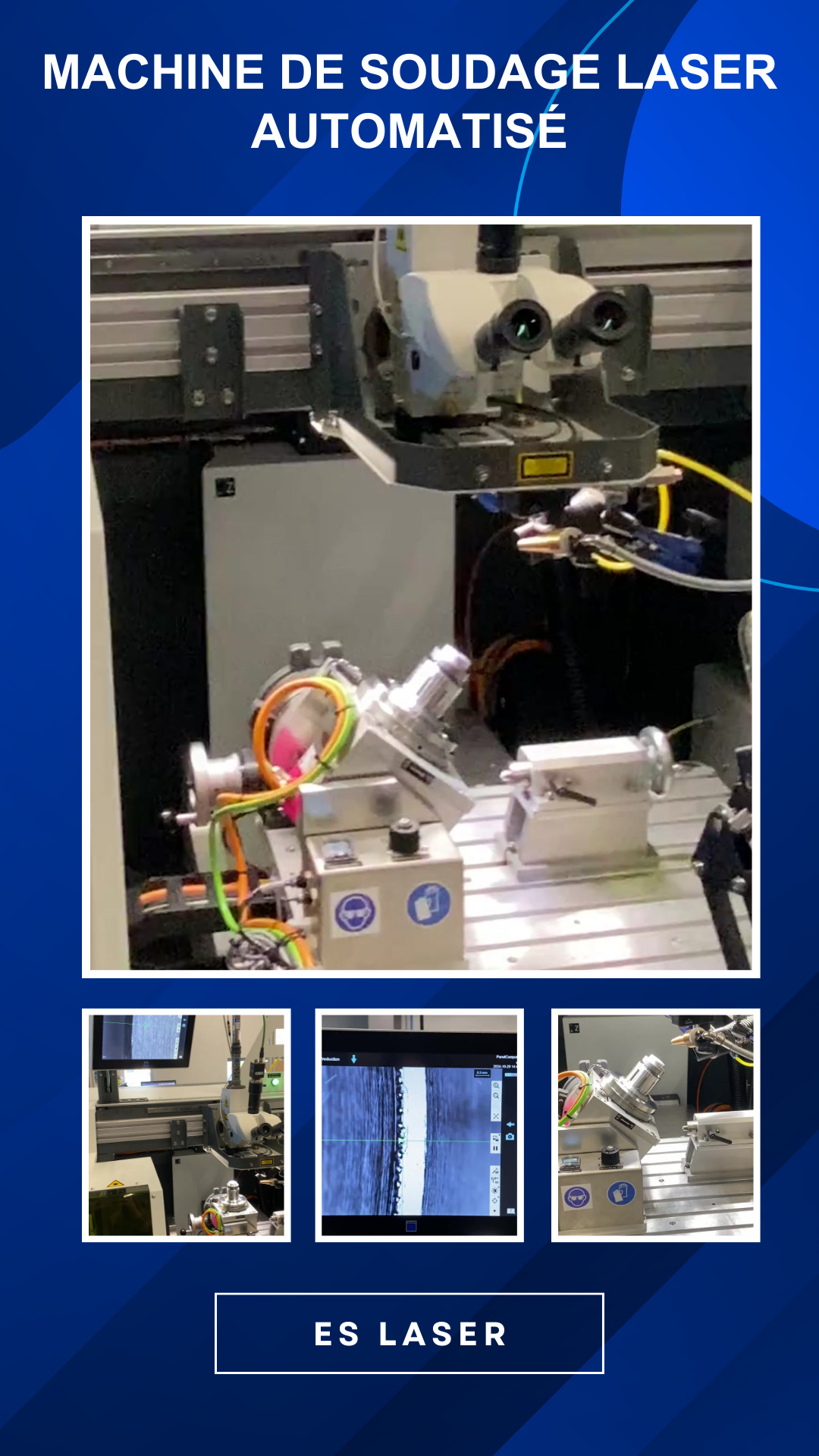

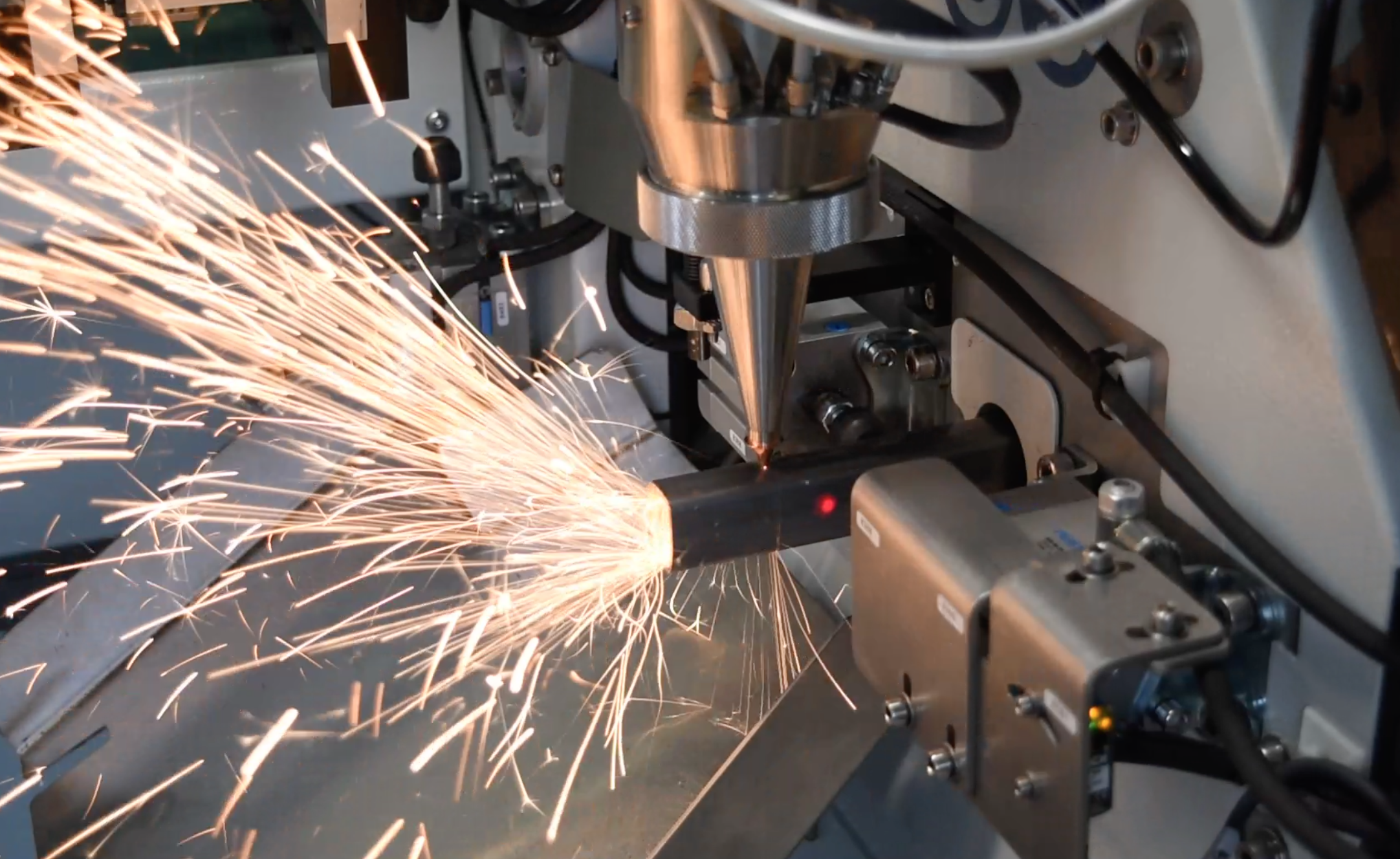

ES LASER has developed a customized 4-axis cutting machine that allows multiple operations to be carried out in a single step for one of its German customers.

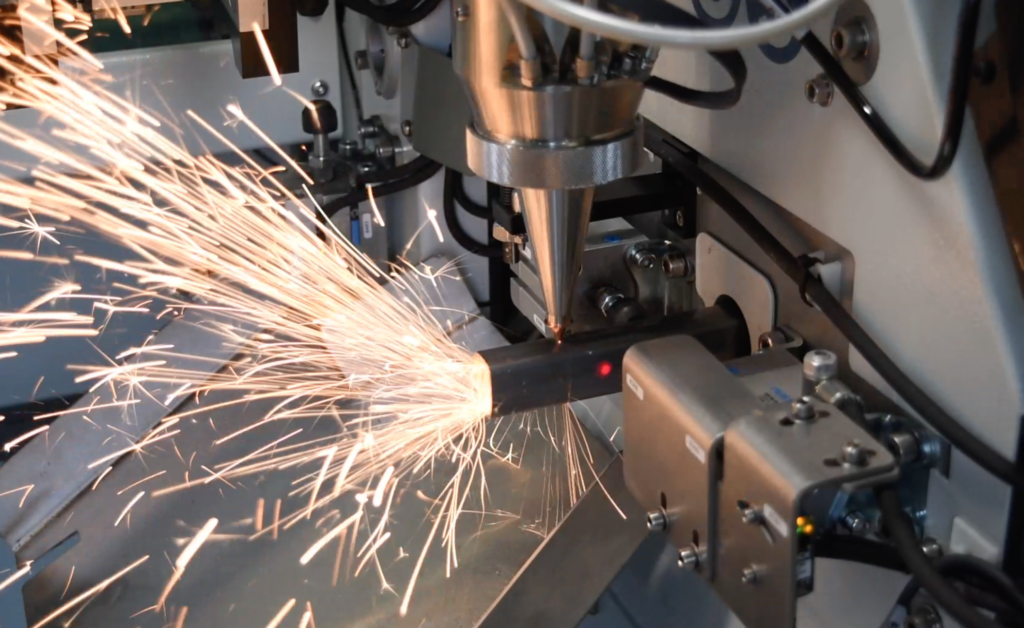

This 4-axis laser cutting machine processes rectangular steel tubes up to 6m long and with thicknesses from 2mm to 4mm, by simple adjustment.

- Multi-application machine: Cutting, Drilling, Cleaning

- Cost reduction

- Speed and ease of execution

- 2 hours of autonomy

Using the machine is quick and easy!

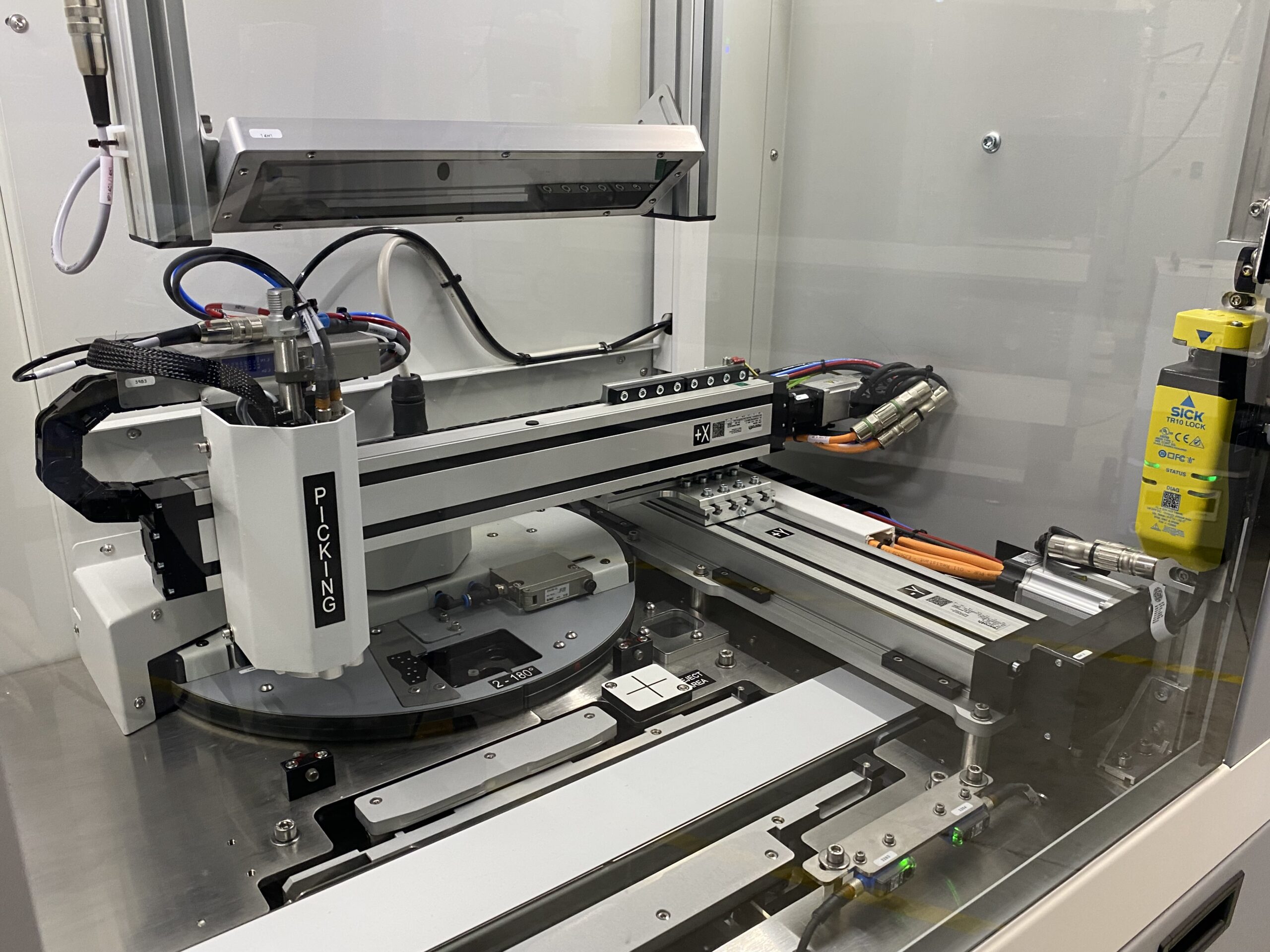

An operator just has to position several tubes on the belt and then select the parts to be produced using the HMI.

After loading the tubes, the operator selects the pre-registered part numbers from the software and starts the program. The machine performs the tasks fully automatically. A 2000 Watt fibre laser first drills fine holes of 5 mm diameter to ±0.1 mm accuracy. High-pressure nitrogen is used as the cutting gas to ensure optimum quality. The pressure of the gas also expels particles and pieces of cut sheet metal. Once the various holes have been drilled, the tube is cut. Each part is transported by a gripper arm to an automated wire brush cleaning system to remove any residue inside the parts. The finished part is then placed on a conveyor belt and transported out of the system.

The production program developed by ES LASER enables a fully automatic process and helps to save raw material. The program calculates the optimal production sequence that uses the least amount of material possible. Operator intervention is only necessary in the event of a malfunction.

For quality control, production information is recorded in a database. This allows performance to be constantly evaluated and, if necessary, further optimised.

Our laser machines are unique, they are entirely designed and manufactured in our workshops, drawing on the expertise of our engineers and our 30 years of know-how.